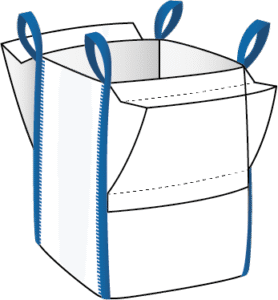

Tunnel Loop Bags

At Nandishwari Packaging, we manufacture high-performance Tunnel Loop Bags (also known as Tube Loop FIBC Bags) designed for safe, efficient, and cost-effective bulk material handling. These bags feature integrated side tunnel loops that allow forklifts to lift the bags without additional handling equipment — ensuring smooth and secure transportation across various industrial applications.

Our Tunnel Loop Bags are widely used in sectors such as agriculture, chemicals, construction, and mining, offering a reliable solution for packaging and transporting dry, flowable materials.

Key Features of Tunnel Loop Bags

- Strong Tunnel Loop Design

Integrated side tunnels stitched into the body fabric provide excellent load distribution and lifting strength. - High Load Capacity

Designed to carry heavy bulk loads ranging from 500 kg to 1500 kg, depending on the requirement. - Durable Construction

Made from high-quality woven polypropylene (PP), with optional UV stabilization for outdoor storage protection. - Customizable Options

Available with various filling and discharge options like spouts, duffle tops, or open tops, as well as flat or spout bottoms. - Moisture & Dust Protection

Optional inner liners (LDPE or aluminum) and fabric coatings to protect moisture-sensitive or fine powder products. - Space-Saving & Stackable

Designed for optimal storage efficiency — easy to stack, store, and transport.

Applications of Tunnel Loop Bags

Our Tunnel Loop Bags are suitable for packaging and transporting:

- Fertilizers and Agrochemicals

- Food Grains, Pulses & Seeds

- Cement and Building Materials

- Plastic Granules and Polymers

- Minerals and Fine Powders

- Animal Feed and Pet Food

- Industrial Chemicals

Why Choose Nandishwari Packaging?

With years of expertise in the packaging industry, Nandishwari Packaging is a leading manufacturer of FIBC Jumbo Bags, including customized Tunnel Loop Bags, trusted across India and beyond.

- ISO 9001:2015 Certified Manufacturing Facility

Located in Vatva, Ahmedabad, our plant is equipped with advanced weaving, stitching, and finishing machinery to ensure top-quality output. - Tailored Solutions

We offer custom dimensions, printing, liners, discharge systems, and more — tailored to your exact material handling needs. - Commitment to Quality & Durability

Every bag is produced under stringent quality controls to ensure performance, safety, and compliance with international standards. - Eco-Friendly & Recyclable

Made from 100% recyclable PP fabric, supporting sustainable packaging goals. - Timely Delivery

Our streamlined production and logistics systems ensure on-time deliveries — every time.